I just got this assembled last weekend.

printables, complete with F3D file.

This is a battery adapter that will allow you to insert D cell batteries into a LiitoKala Engineer Lii-500. I included the Fusion 360 file, so you can customize it to fit other applications, but odds are it will fit most 4+ 18650 based chargers that are also compatible with Ni-MH.

It prints in two halves that I simply hot glued together around their perimeter. It’s not like this part is going to see very high loads… The parts are designed to print without supports. My copies are 20% infill (you could easily go with less) and 3 walls for an overall wall thickness of 1.16. Wall thickness is something I wouldn’t change, at least for the battery side so the battery terminals don’t eventual fail. The batteries are a very slight interference fit to ensure a robust electrical connection.

For terminals, I used 8mm wide nickle strip. I’m sure you could use something else, but I had some on hand and it seemed like an obvious application. Connections between the two halves were made via wires and solder.

There’s supposed to be a heat sensor on the positive contact that you are rendering useless. That said, given the lack of longevity of every nickel battery I’ve tried on the past couple of decades, I don’t think the charger manufacturers take this guideline seriously.

This is true, but at the default 500 mAh charge rate it seems unlikely that much heat will be generated? Worst case of 100% of input voltage getting converted to heat would be 700mW or so of energy needing to get dissipated per cell.

Yeah, the big cells can handle that just fine. The charger would overheat first unless a cell is shorted, which only possible with NiMH/NiCd if the charger malfunctions or the battery is physically damaged.

The charger circuitry should be designed to avoid that issue entirely.

It’s not dangerous. It just degrades the batteries.

If “10,000 mAh” (if they’re half that I’ll be happy) batteries are heating while charging at 500mA odds are they’re not in great shape to begin with.

given the lack of longevity of every nickel battery I’ve tried on the past couple of decades

Early Ni-CADs and NIMHs I agree with that assessment. However for low duty cycle applications the 3rd and 4th gen Eneloop type technology NIMHs perform very well for me. I’ve got about 20 operational cells I purchased in 2011 from an original batch of 30.

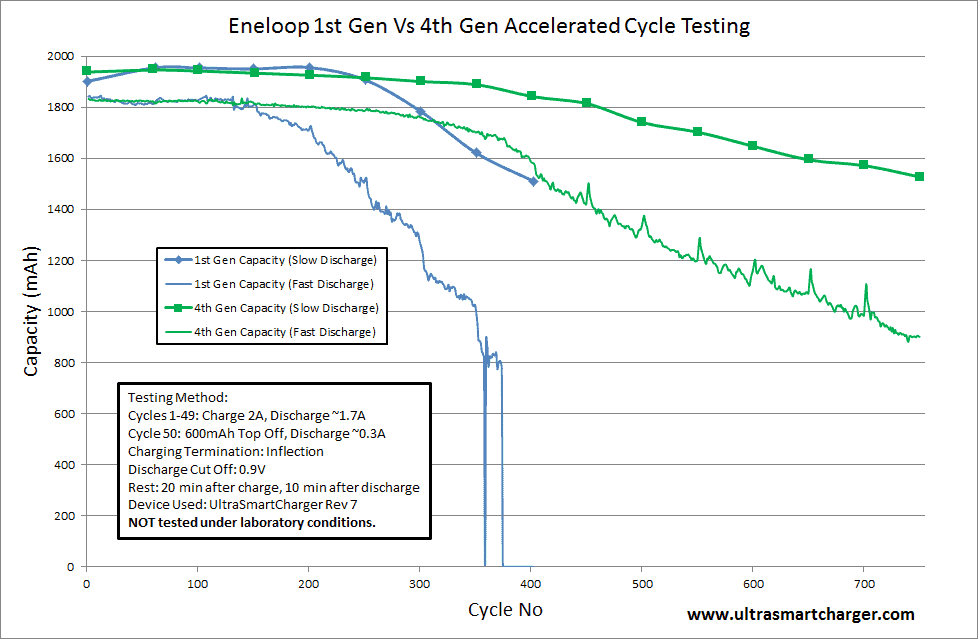

This isn’t my data, but my anecdotal experience matches this:

If you have issues with longevity you should focus on getting a new charger. Many chargeres over charge the batteries and completely ruins them. Do it once and they are ruined forever and they wont hold charge anymore. Take a look at lygte-info.dk (don’t worry the site is in English) where he reviews chargers. I can recommend many of the xtar chargeres.

Direct link for comparison of chargeres. https://lygte-info.dk/info/roundCellChargerIndex UK.html

What do you D batteries for?

I hadn’t used them in many years but then my gf got me the hot wheels set I asked for at Christmas 30 years ago and never got and it uses D batteries. I’m planning to make a wall adapter for it.

The hot wheels set is Criss Cross Crash and it’s probably the best toy ever made. They haven’t changed it in the last 30 years.

Amusingly, this is almost exactly the reason why we have D sized batteries. The batteries are for a Criss Cross Crash, which I also never owned for a kid. But we got it for our kids (one of the perks of being a parent - you can buy the toys you wanted as a kid but didn’t get).

I initially purchased a pair of these chargers to charge 18650s for… high power flashlights. Yes, that’s a thing, go check out [email protected]. Then I started tearing down older laptop batteries to harvest 18650s for a DIY electric scooter. Then we had kids and now these chargers see a lot of use for Mi-MH

deleted by creator

Def not UL Listed

This is true, but the risk is very low. Amusingly, the chargers themselves are not UL rated despite being fairly highly regarded. Maybe I’ve got bigger problems.

You really don’t know the risks unless you open it and minimally reverse engineer it. The charger shouldn’t be very complicated and it’s not directly connected to mains so that is nice. Charging chips are super simple and there are not too many ways to screw those up, unless they do.

If anything at all is shady, it’ll be the power brick or the way the USB plug is powered. If the brick is crap and somehow starts passing mains, I am willing to bet that the USB plug will pass the bulk of the current through you or whatever is connected to it. It’s something to check, anyway.

Reverse engineering to determine safety is what UL does. If anything here, the charger needs to account for fucked batteries with fail-safes but as long as the batteries are fine, it shouldn’t be a problem

(I can’t disagree with you, cause you ain’t wrong. ;) I do probably need to clarify my point though.)

That is exactly my point about the device not being UL rated. More than once, I have needed to add or replace poor ground connections to the chassis of some device, when applicable. If there is a failure point, it’s usually where there were cost savings is involved and generally not with the charging circuit itself.

Most battery charging ICs have decent fail-safes for bad batteries. It’s just economical to use the same, or similar, generic IC across hundreds of products. (The TP4056 (and clones) is a decent example of wide adoption, but it’s not quite a 1:1 with this particular application. It has good trickle charging and a temperature safety, but not battery chemistry logic, that I am aware of.)

Again, it’s just something to look for when inspecting rando devices. To your point, cloned charge regulators may have deleted safeties, so that is a thing.

What is anymore, in the age of Amazon and Alibaba

¯\_(ツ)_/¯

I love the idea of being able to fit 4 big D’s

So does your mom!

I love the idea of being able to fit 4 big D’s

I’m more interested in knowing whether the charger actually supports that type of usage.

This is a four bay charger that supports the chemistry already. The only thing it didn’t support was the battery from factor, so adapter to the rescue.

The chargers typically support 3 sockets, you could adapt one to fit two big D’s for Double Power.

Bold move!

Not really bold, just a cool hack. There is pretty much nothing to go wrong.

I think my preference would be to cover the parts that would short on the bottom, but that’s because I’m a messy person that would probably discharge the batteries accidentally 😹

I did something similar back in the day, but I did it in a much more boring fashion by getting a 4 D cell holder from Radio Shack and wiring a Deans plug to it, so I could plug it into my R/C battery pack charger. Your solution is a bit more elegant, in a way.

FWIW I bought similar AA and triple-A of this brand to replace regular alkaline batteries my kids use in their VR controllers. It was getting expensive with the disposables, so I decided to try rechargeable batteries even though I’ve had poor luck with them in the past. This brand is doing really well and has paid for themselves handily in saved disposable batteries. Worth it not throwing more crap in the landfill, too.

Yup, we have tons of rechargeable AAA and AA batteries that are used all the time.

why not just buy a proper charger?

Because you don’t have to with the right tools and the right mind.

The less e-trash the better.

The only difference is literally the case itself, which can be solved with this print and some contacts.

Anyone with some electrical knowledge can tell you that this solution is totally fine.

why not

just buy a proper chargerwaste $50 ?deleted by creator

A better solution: buy a D-cell battery charger and get spacers for whatever other battery you desire. Then you can charge any battery, or even use the spacers with smaller batteries in devices that require bigger batteries.

The only difference between D and AAA is capacity. They’re all nominally 1.5V.

This cost well under $5 and generally feels less wasteful than simply buying another charger. Yeah, it took about 30 minutes of CAD time and another 30 or so of assembly, but I involved my kids with the intention of getting them interested in making/designing things.

If you’ve got a 3D printer, then your next project should be to make some plastic spaces for smaller batteries! In fact, it’s such a simple project you could set the child labor force on it…

I actually own a D-cell-capable charger (also takes other sizes down to AAA). I guarantee you that it cost a lot more than this—$50 Canadian before the pandemic. So I can understand the attraction of hacking one of the cheaper chargers.